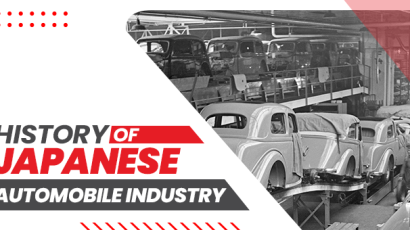

The Japanese automobile industry is a record-breaking industry in the world that has been raising the bar high for innovations. Being the third largest automobile manufacturer and exporter, Japan has been able to make a name for itself for manufacturing state-of-the-art vehicles.

One of the reasons why the Japanese automobile industry is considered the best is because they focus on the continuous enhancement of the product, implementing the latest safety measures, and integrating transformational technology. Furthermore, their focus on adopting the latest technological advancements has allowed them to streamline environmentally safe, fuel-efficient, and high-functionality cars.

With the production of safe, feature-rich, and high-performance cars, Japanese vehicles have gained the trust of millions around the world. The fact that makes their journey of success more commendable is their modest beginning. Let’s take a look at how the Japanese automobile industry rose to the top and managed to conquer the industry:

The Beginning

It all started with Komanosuke Uchiyama, a technician in his early twenties working at Sorinshokai, who made two trial vehicles in 1902. Komanosuke made the chassis and body of the vehicles himself and utilized the engine brought by the manager at Sorinshokai from the United States.

In 1904 Torao Yamaha built a bus made with Japanese equipment that can accommodate ten passengers at a time. Three years later, in 1907, Komanosuke launched an entirely Japanese-made gasoline car. Then in 1917, Mitsubishi Zosen manufactured 22 cars which was the first mass production of Japanese cars.

During that time, American automobile makers started building cars in Japan, and by the year 1930, they were producing around 20 000 units. Whereas, at the same time, Japanese automobile makers were producing just about 500 units.

After experiencing a Russo-Japanese war in 1904-1905 and then an earthquake in 1923, the nation realized the impending need for automobiles. Thus, in the year 1935, automobile, aircraft, and electric industries underwent a booming growth due to the rising needs and demands of the people.

In response to public demand, the government of Japan passed the Automobile Manufacturing Industries Act in 1936 that empowered Japanese automobile makers. By 1937, Japan had 16 companies manufacturing automobiles.

The Emergence of the Automobile Industry

After World War II, Japanese industrial conglomerates had to disband, due to which many companies had to reform again. Japan’s government discerned that the growth of the Japanese automobile industry depends upon the production of vehicles domestically.

Automobile manufacturers started working on the production of parts domestically which then played an active role in uplifting the economy. In 1955, Suzuki introduced Suzlite, Fuji introduced Subaru and Mitsubishi introduced Mitsubishi 500. Now the manufacturers were not just focused on producing general use cars; this time around, they started working on making the cars fuel-efficient. The best thing about these cars was that they were available for consumers at an affordable price range.

In 1960, Toyo Kogyo-later, to be recognized as Mazda– launched a 360cc coupe, and then a year after that, in 1961, Toyota introduced its 700cc coupe. All these innovations were due to the government support that empowered automakers to produce small affordable, and fuel-efficient cars.

Along the way, manufacturers realized that they require more automation for the production of automobiles. This gave rise to the Japanese Automotive Manufacturers Association (JAMA), formed in the year 1967. The association dealt with Japan’s economic changes and regulated automotive imports.

In 1970, manufacturers began adopting advanced technological tools and robotics to streamline the production process. This allowed automobile sales to skyrocket as the mainstream consumer market started investing in Japanese cars.

In the mid-70s, around 50% of the households owned cars. This heavy influx of cash gave the Japanese automobile industry the added benefit of further innovating their development processes and designing phenomenal cars.

Oil Crisis and the Maturing Domestic Market

The rapid growth of the automobile industry took a nosedive in 1973 when Japan suffered from the oil crisis. However, the impact wasn’t that profound. While American cars featured large, high-powered engines, Japanese cars, on the other hand, were compact and designed to leverage fuel efficiency. Moreover, due to the utilization of light parts and innovative material usage such as tension-steel sheeting, Japanese automobiles found their way to the global markets.

The aftermath of the crisis had a silver lining for the Japanese automobile market. It gave rise to small passenger cars and mini cars that became the rising factor for the expansion of the market. They garnered maximum sales for being available in economical packages and for complying with the stringent government policies for exhaust emissions. These mini automobiles took the lead by targeting young drivers and women.

By 1985, the Japanese automobile industry started to gain more traction and was gearing up to make its mark in the industry. From enhancing the manufacturing process to adapting cutting-edge technological tools, Japan was now deemed incomparable when it comes to automobiles.

The factors that kept Japan’s automobile industry on an upward trajectory are their willingness to improve their products and their forward-thinking approach. This time around, Japanese automakers were focusing on making their cars recyclable.

To address the rising environmental issues, manufacturers started working on it diligently and built organizations to deal with such issues. They aimed to make informed decisions regarding these matters and upgrade their designing, development, management, sales, scrapping, and recycling processes.

Manufacturers, now, were focusing on reducing exhaust emissions, further increasing the fuel-efficiency, and optimizing production to reduce air, noise, and water pollution. In addition, they are also taking measures to promote traffic safety, such as seatbelts and helmets. JAMA’s action plan is to integrate advanced technology such as power steering, car navigation system, driving assistance, adaptive braking systems, safety sign detection systems, etc., into the vehicles.

The action plan was restricted to manufacturers but also included educational and safety campaigns that can enable drivers to be aware of all the rules and regulations, improve their driving experience, and prevent road accidents as much as possible.

Luxury Cars on the Rise

With the market advancing from utilizing automobiles to transporting one point to another, to having them for the same purpose but with high-end features that add value to their lives. One thing that all Japanese cars share is reliability. Leading automobile makers like Toyota have produced some of the most remarkable vehicles, such as the Land Cruiser and Corolla, earning high appreciation for the seamless maintenance and resilience they offer.

The adoption of luxury cars gave rise to large cars with DOHC engines, auto transmission systems, and whatnot. As a result, the average price increased from 1.1 million to 1.5 million. As price tags started to reach the sky, the average time for ownership of a vehicle also increased. From owning a car to an average of two years increased to having it for around a decade.

Conclusion

Japan, to this day, still ranks as one of the largest manufacturers of cars, trucks, and buses. They have maintained their place in the market by analyzing diversified market demands and then working their way to meet and exceed expectations.

Japan’s alliances with the top automobile manufacturers help them to offer efficient, high-performance, and advanced products to the market at affordable costs. The winning aspect of investing in used Japanese cars is that they offer outstanding functionalities without costing a price that puts a hole i